How long do Flex PCBs last compared to rigid ones?

The lifespan of Flex PCBs and rigid PCBs depends heavily on the respective operating conditions, material quality and design. Flex PCBs are designed to withstand repeated bending and movements, often providing higher durability than rigid circuit boards in dynamic applications. With optimal design and under suitable operating conditions, Flex PCBs can achieve comparable or even longer lifespans than rigid PCBs. Decisive factors include temperature, humidity, vibrations and the quality of materials used.

Can I convert my existing PCB design?

In most cases, it's possible to transfer an existing circuit board design to a flexible PCB. Of course, some important aspects must be considered, including:

- Selection of suitable materials

- Bending radius

- Placement and mounting of components

- Specific design rules for flexible circuits

Where necessary, our experts make suggestions for adjustments to optimally utilize the advantages of Flex PCB technology. Our Flex PCB specialists always seek the best solution for you.

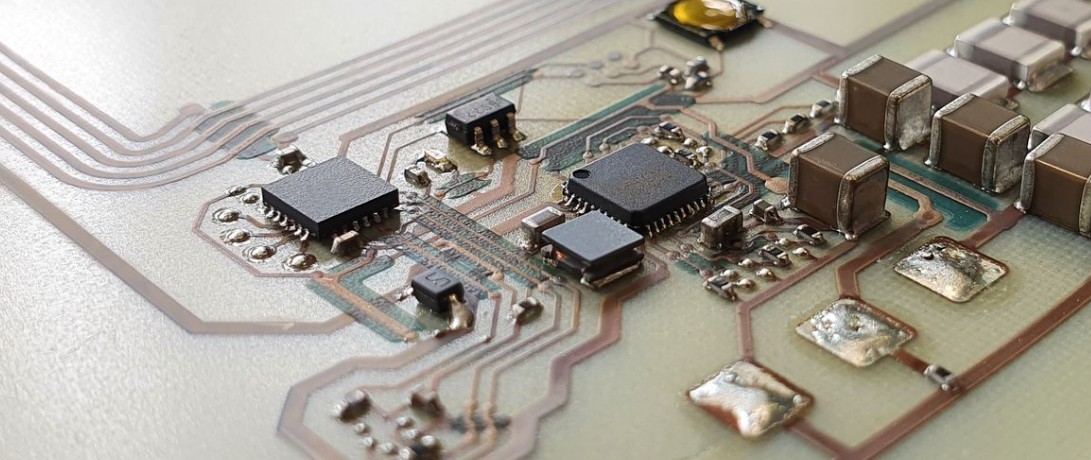

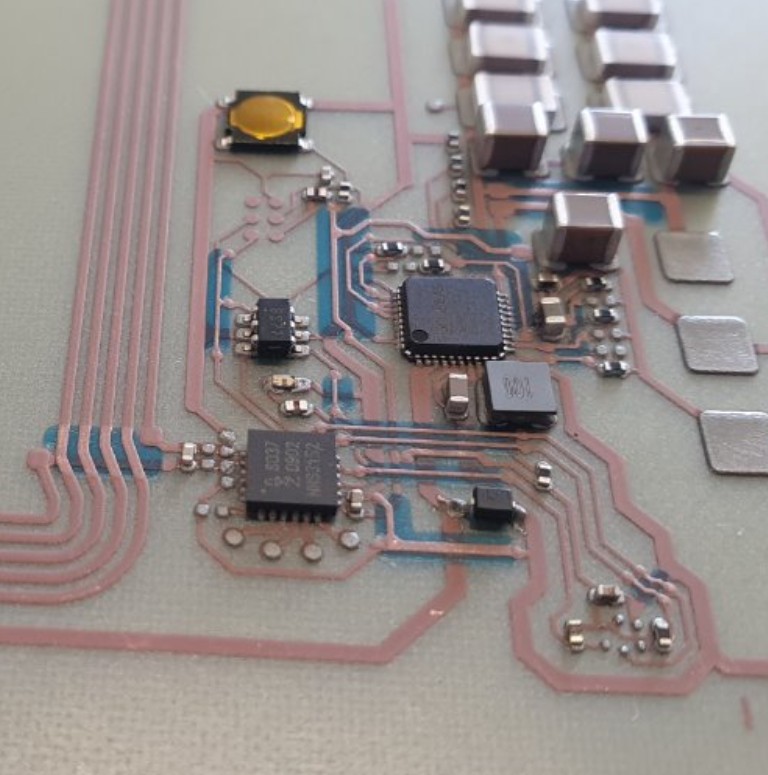

How do you handle component assembly on flexible PCBs? Can you use standard SMD production lines?

Yes, our flexible PCBs are fully compatible with standard Surface Mount Technology (SMT) assembly processes. We use reflow-solderable inks that enable seamless integration with your existing automated SMD production lines.

Our Flex PCBs can be processed using conventional sheet-based assembly methods, allowing you to leverage your current manufacturing infrastructure without requiring specialized reel-to-reel equipment. This compatibility ensures cost-effective production scaling and maintains your established quality control processes.

The reflow soldering process works reliably with our printed conductive traces, delivering strong, durable solder joints that maintain their integrity even under repeated flexing cycles.