Solutions for defense applications: Miniaturized, reliable, and customizable.

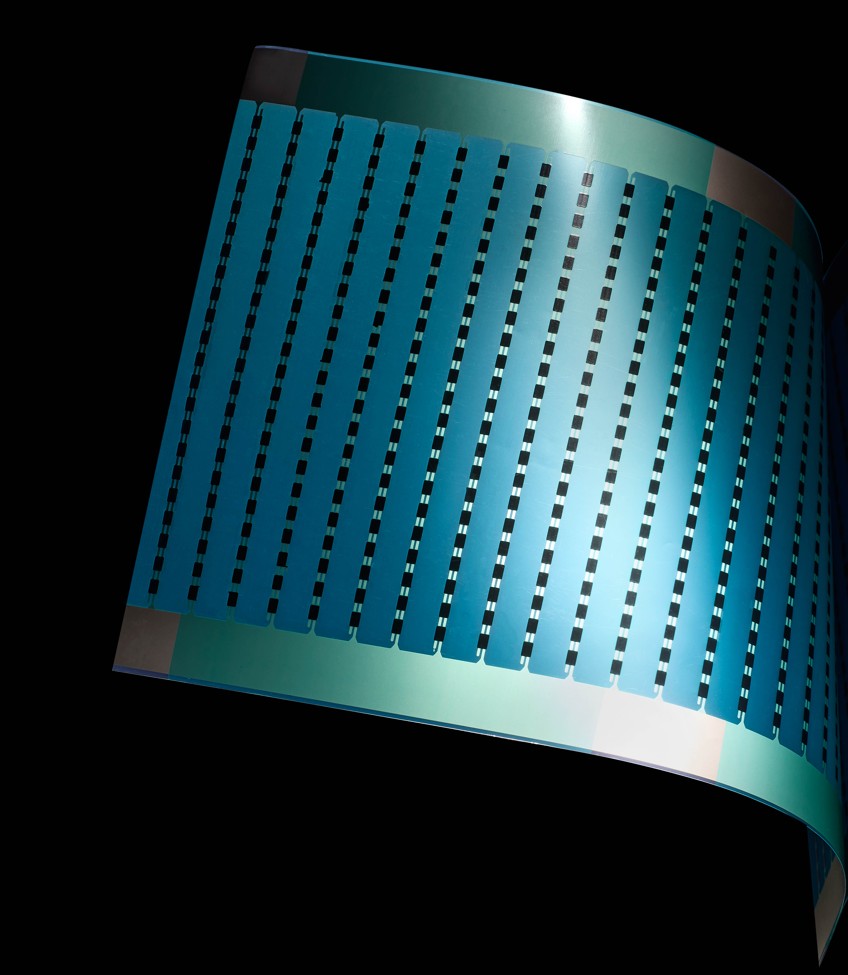

Flex PCBs, sensors, heating elements, and antennas for challenging requirements.

Flex PCBs, sensors, heating elements, and antennas for challenging requirements.

1

Military systems must become lighter, more compact, and energy-efficient to increase mobility, stealth, and operational duration.

FLEXOO's solution: Extremely thin, Flex PCBs and printed sensors replace rigid circuit boards, significantly saving weight and space.

2

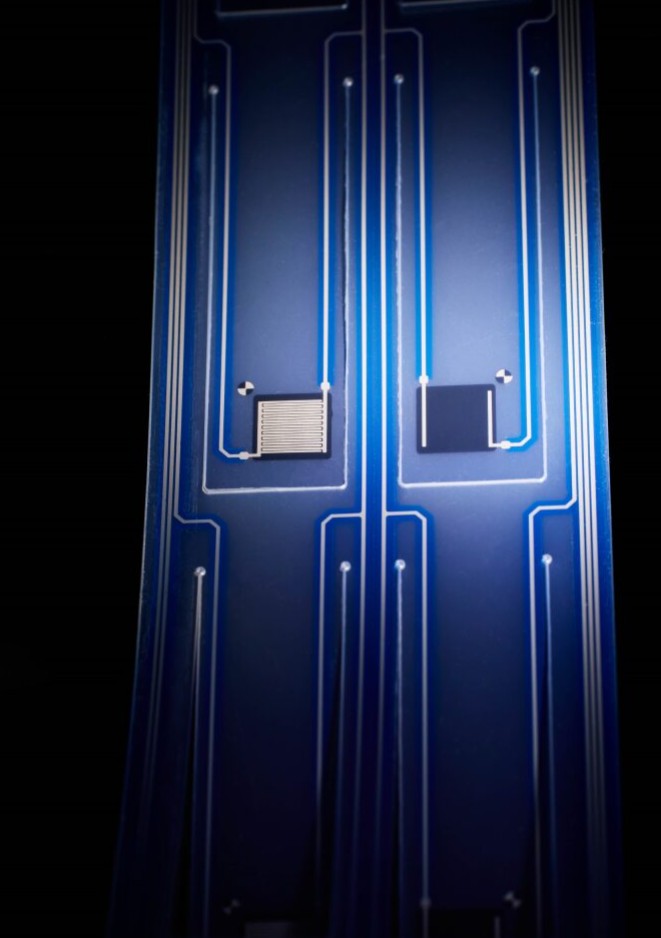

Modern defense systems require integrated, multifunctional components combining sensors, antennas, heating elements, and circuits.

FLEXOO's solution: Printed military electronics enables integration of multiple functions on one flexible substrate - combining temperature/pressure sensors, antennas, and heating elements on a single Flex PCB.

3

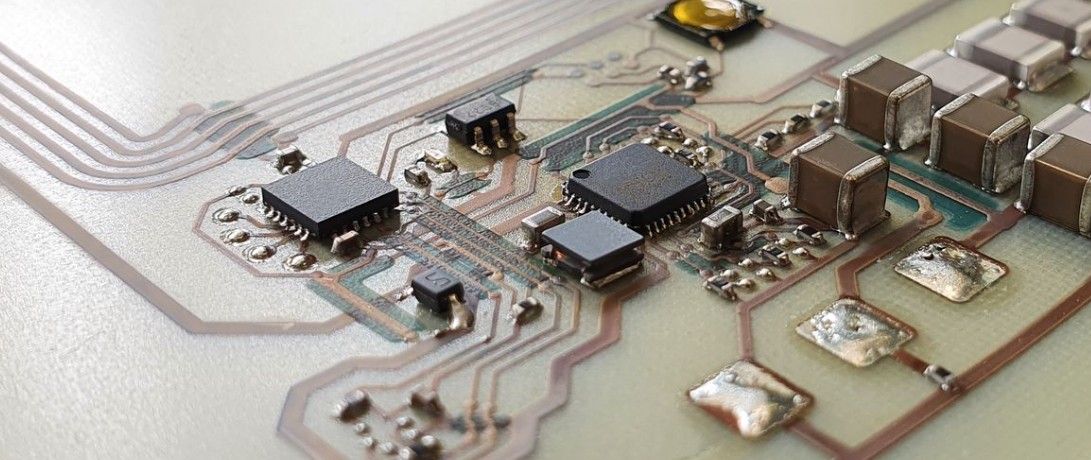

Defense applications demand highest reliability under vibration, temperature fluctuations, humidity, and mechanical stress.

FLEXOO's solution: Robust, vibration-resistant printed sensors and Flex PCBs withstand extreme environmental conditions. Monitoring solutions enable early fault detection and condition monitoring.

4

Spare parts and custom adaptations must be available in the field or within short timeframes, especially for failures or upgrades.

FLEXOO's solution: Printed military electronics can be produced quickly, flexibly, and cost-effectively - ideal for military spare parts and prototypes.

5

Modern systems demand precise real-time monitoring of temperature, pressure, and other parameters to increase operational safety and lifespan.

FLEXOO's solution: Printed temperature and pressure sensors plus monitoring solutions enable comprehensive component and system surveillance - even where conventional electronics cannot fit or on curved surfaces.

6

Communication systems (e.g., antennas) must often be integrated inconspicuously, space-efficiently, and reliably into structures.

FLEXOO's solution: Printed antennas can be directly applied on or into housings and structures, offering new possibilities for covert communication and sensing.

7

Electronic systems must not overheat and must function even at low temperatures.

FLEXOO's solution: Printed PTC foil heating elements provide targeted, energy-efficient heating of components and surfaces critical in defense systems.

8

Material scarcity, cost pressure, and sustainability are gaining importance in defense.

FLEXOO's solution: Printed military electronics reduces material consumption, simplifies production, and enables more environmentally friendly manufacturing processes.

Energy-efficient heating elements for targeted thermal management of critical components at all temperatures.

Printed sensors for precise real-time monitoring of critical parameters without any design limitations.

Flexible circuit boards for miniaturized, weight-reduced systems with reliability under extreme conditions.

Intelligent surveillance systems for early fault detection and continuous condition monitoring.

Let us solve your military system challenges together with customized printed military electronics.

Printed military electronics offers significantly shorter development and production times than conventional methods.

Prototypes can be created within days, series production starts in 2-4 weeks depending on complexity.

Particularly for spare parts and field adaptations, this technology provides crucial time advantages for military system spare parts supply.

Yes, our printed military electronics solutions are developed to withstand harsh conditions, e.g. extreme temperature fluctuations (-40°C to +85°C), vibrations, humidity, and mechanical stress. All components undergo comprehensive quality testing.

Printed military electronics reduces costs through multiple factors: lower material consumption, simplified production processes, elimination of complex assembly, and small-series manufacturing capability without high tooling costs.

Particularly for spare parts and custom adaptations, cost savings of 30-50% compared to traditional methods are achieved. Additionally, logistics and storage costs are reduced through fast, demand-based production.