BaMoS

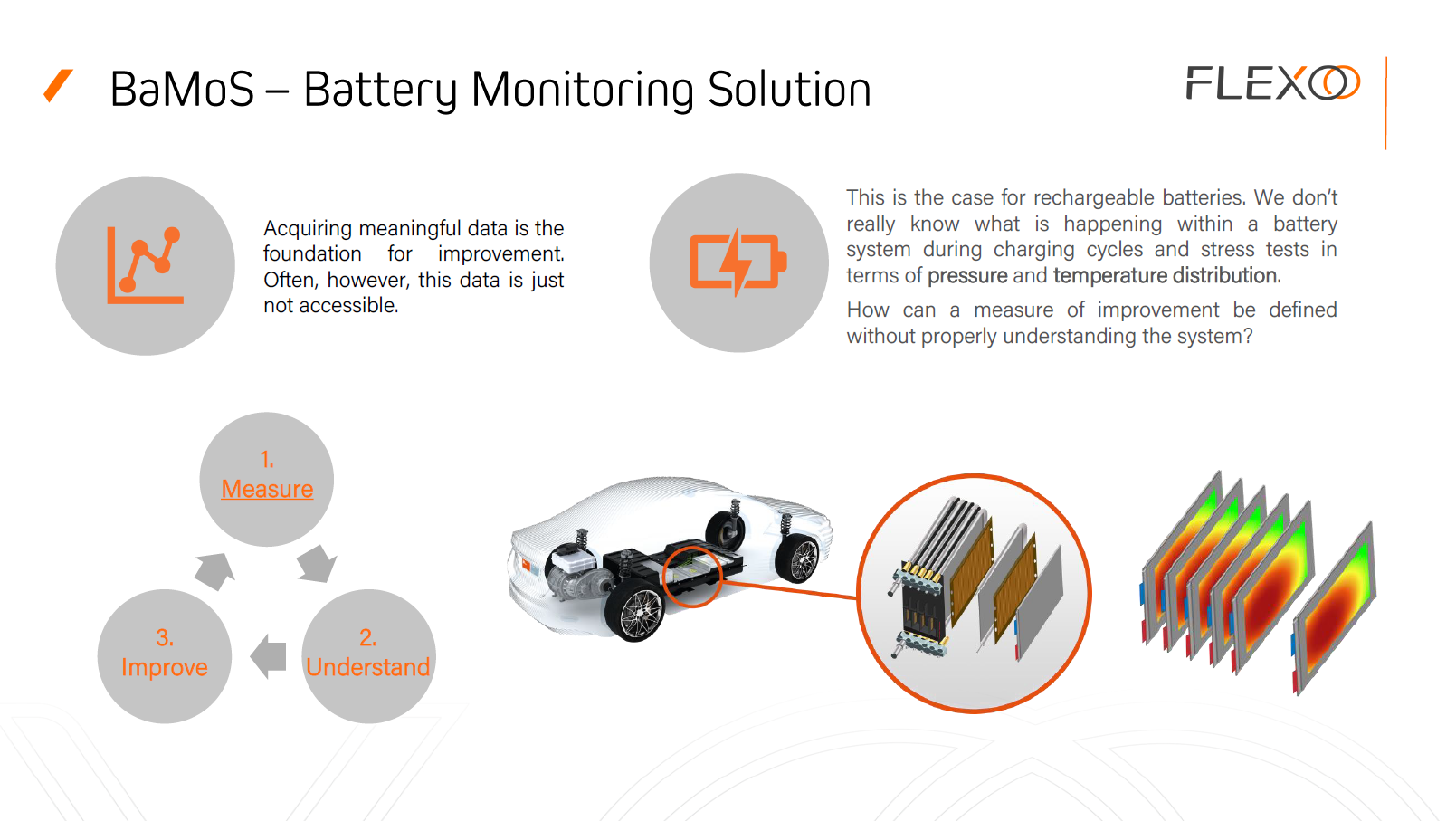

The Innovative Battery Monitoring Solution for Automotive Applications

In various industries, batteries serve as vital components, powering a wide array of applications.

Whether in electric vehicles (EVs) or stationary energy storage systems, the performance and longevity of batteries are of utmost importance. BaMoS introduces an innovative approach to battery monitoring, utilizing ultra-thin printed pressure and temperature sensors to capture detailed battery data down to the individual cell level.

With BaMoS, Flexoo offers a comprehensive battery monitoring solution, comprising sensor foils, electronics for data collection and processing, and software for real-time visualization, storage, and analysis.

The flexibility of BaMoS extends to customizable pressure and temperature sensors, allowing adaptation to specific customer requirements.

Throughout the charge and discharge cycles, batteries undergo volume fluctuations, resembling "breathing”.

BaMoS capitalizes on this phenomenon by deploying printed pressure sensors strategically around and between battery cells. Monitoring these pressure changes provides insights into cell state-of-charge, facilitating preventive measures against overcharging and enabling cell balancing. This optimization maximizes battery capacity and lifetime by rectifying variations in the state of charge between cells within a battery pack. Moreover, BaMoS sensors can provide data from each individual cell, offering a granular view of battery health.

Optimal pressure significantly impacts battery lifespan, potentially improving cycle lifetime by 30 to 40 percent.

Temperature monitoring is equally crucial, especially in environments where lithium-ion batteries are deployed. Temperature variations can affect battery performance, with cold conditions posing particular challenges. BaMoS integrates printed temperature sensors to detect temperature fluctuations, enabling proactive identification of potential issues. In colder climates, BaMoS can activate printed heating elements to raise battery temperature, enhancing energy output. Additionally, temperature data aids in optimizing cell balancing strategies.

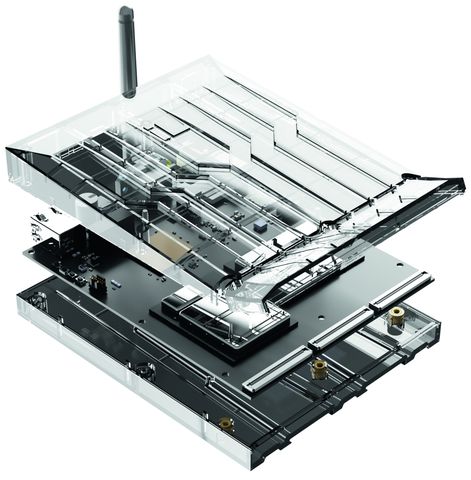

Product specification

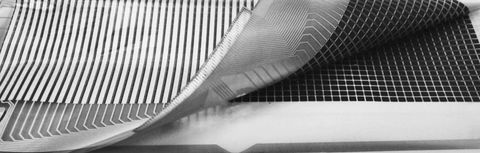

- Matrices of pressure and temperature sensors printed on thin foils

- Both standard and custom-made layouts

- Prime pressure sensor architecture available

- Humidity sensing and heating on demand

- State-of-the-art crosstalk-less solution with superior signal quality

- Resolution: Up to 96x96 Pixels; 12-bit signal converting

- Stand-alone operation

- Enhanced EM interference shielding

- Communication via CAN, Ethernet, USB, WiFi and Bluetooth

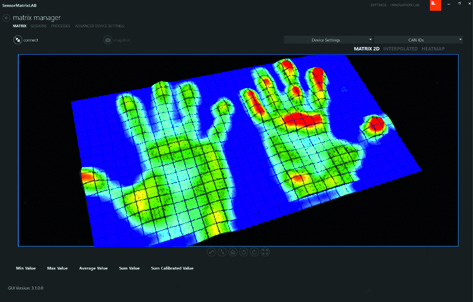

- Live 2D and 3D visualization

- Data storage and analysis

- Real-time streaming via API

- Sensor calibration option

- Customized data capturing:

- Simultaneous read-out of several foils with different parameters

- HDR function to get the best out of every sensor

BaMoS finds extensive applications in continuous monitoring of batteries in stationary energy storage systems. Battery storage facilities rely on robust monitoring solutions to ensure optimal performance and longevity, making BaMoS an invaluable tool in this regard.

BaMoS enables End-of-Life (EOL) tests for batteries, providing comprehensive monitoring during the entire lifecycle. This capability allows for the assessment of battery health and performance over time, aiding in the identification of degradation patterns and informing maintenance or replacement decisions.

Learn more about our Software SensorMatrixLAB.

Downloads

Let’s Start to Work on Your Challenge!

Ready to take the next step? Reach out to our sales team today to schedule an appointment with our dedicated sales manager and discover how we can tailor our solutions to meet your needs.