In-Situ Cell Sensors for Safe, Economical, and Reliable BESS

Stop BESS fires!

Safety begins where the risk originates: at the cell level of each individual battery in the battery pack. This is exactly where our calibratable sensors are positioned, measuring with high precision in real-time.

This gives you a crucial time advantage before thermal runaway occurs. Your Battery Management System and AI logic make better decisions with the real-time data from our temperature and pressure sensors – ensuring greater safety and optimal performance.

Real-time cellular monitoring of thermal runaway

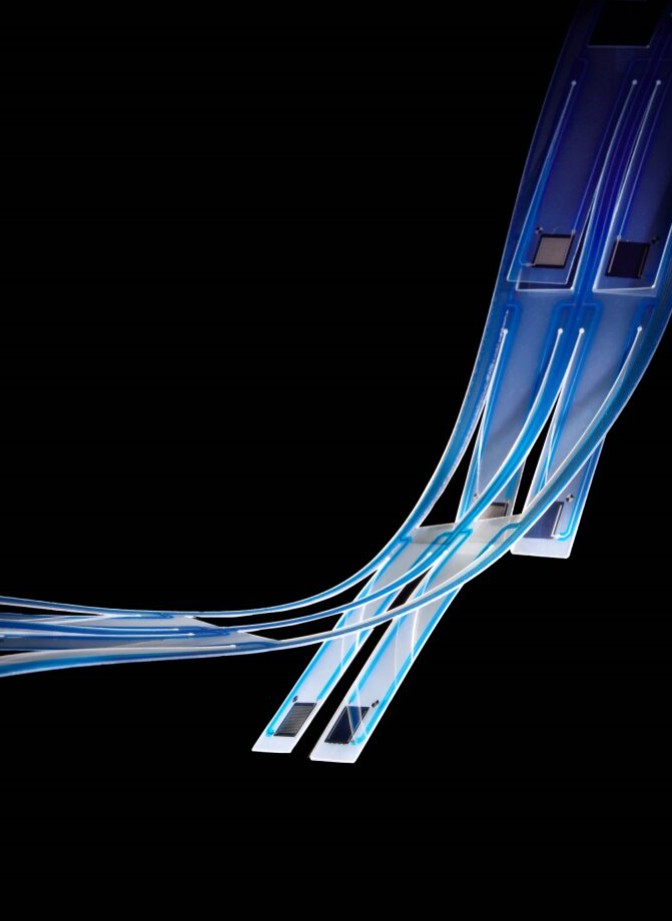

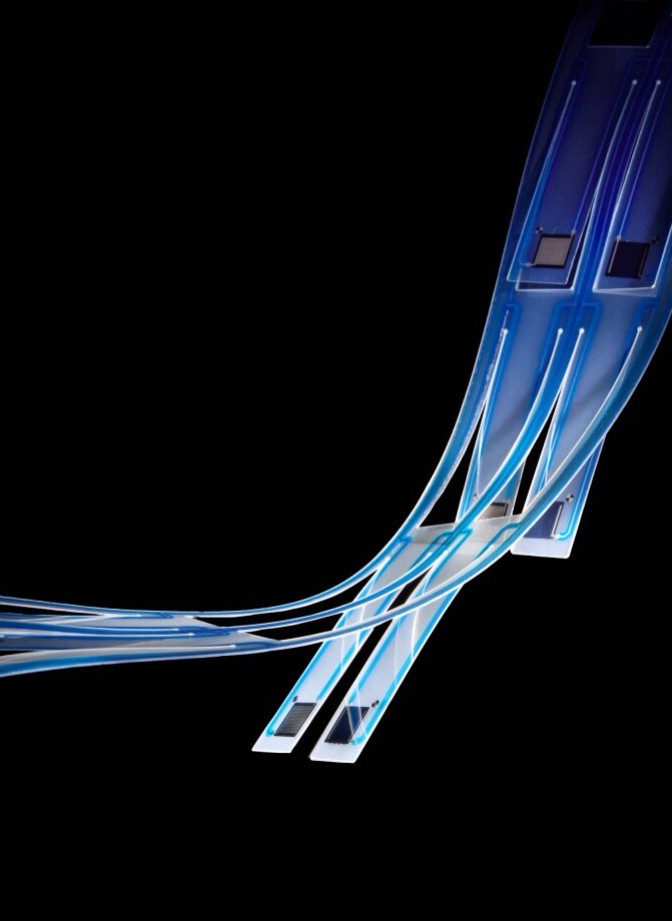

Our high-speed sensors integrate seamlessly into the battery pack design.

These ultra-thin measurement sensors easily fit into the spaces between battery cells without changing the height of the BESS battery pack. Printed on highly robust, flexible films, they can accommodate any cell-to-pack design.

See our BESS sensors in action

Discover in our case study how our in-situ sensors improve the safety and performance of battery energy storage systems. A customized sensor matrix delivers real-time temperature and pressure data to the BMS – explore the benefits of our technology.

Cell-level sensors boost BESS safety & performance - FLEXOO enables scalable integration without battery pack redesign.

The problem: Safety risks in BESS battery storage

Thermal runaway

Overheating of individual cells can trigger a chain reaction and cause massive fires that destroy entire facilities.

Reduced lifespan

Uneven temperature distribution leads to premature wear and reduced capacity of battery cells.

Insufficient monitoring

Conventional sensors detect critical conditions too late and fail to provide adequate cell-level monitoring.

Our solution: Printed sensors for real-time monitoring

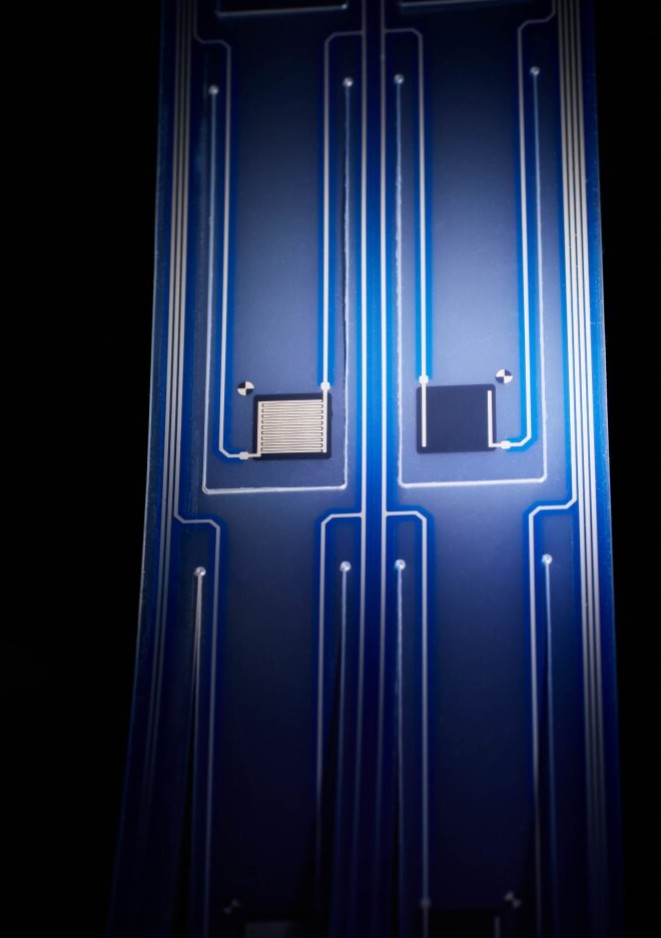

Miniaturized sensors

- Ultra-thin printed sensors integrated directly at the cell level

Precise measurement

- Highly accurate temperature and pressure detection in real-time

Rapid response

- Immediate data transmission to the Battery Management System

Preventive protection

- Early detection of critical conditions before escalation

Advantages of our BESS cellular monitoring sensors

Enhanced safety

- Prevention of costly fires through early detection of hotspots and thermal anomalies.

Extended lifespan

- Optimized operating conditions and uniform temperature distribution extend service life (up to 40%).

Increased efficiency

- Precise data enables improved performance and maximizes energy yield from your battery storage.

Application areas of our BESS cellular temperature monitoring sensors

Stationary storage

Security for BESS facilities for renewable energy sources

E-mobility

Monitoring of vehicle batteries for maximum operational safety

Industrial applications

Protection of critical infrastructure such as UPS systems

Mobile devices

Safety for portable energy storage and consumer electronics

About us: Your partner for battery safety

Many years of expertise in printed electronics for cell-level battery monitoring

Successful collaboration with leading companies in the battery industry

We manufacture the most precise printed sensors available

Frequently asked questions about BESS sensors for cellular temperature monitoring

How do I start with cellular temperature monitoring to increase BESS battery safety?

Start with a functional prototype. Our engineers will support you with integration and evaluation of results. Your test results form the basis for further adjustments.

What customizations are possible for BESS cellular temperature monitoring sensors?

Our sensors can be individually adapted in size, shape, and measurement range to your specific battery types. We customize the film design to match your existing battery pack design. We also offer tailored interfaces for your Battery Management System.

What happens after specifications are finalized?

The Alpha Product stage begins the production ramp-up. At this stage, the battery sensor specification is complete. This is followed by the quality assurance phase with the Beta Product. Typically, you'll receive deliveries for your production in less than six months according to your desired scheduling system.

- Wireless Sensor Real-Time Measurement FLEXOO's wireless sensors enable real-time cell-level monitoring in battery systems, preventing thermal runaway and enhancing safety and performance. read more

- BaMoS In various industries, batteries serve as vital components, powering a wide array of applications. read more

- References Leading global brands and industry experts trust our solutions. Their success with us speaks volumes about the quality and impact of what we deliver. read more